Ballsum workpiece measurement, machine tool contact tool setting instrument, lathe tool setting arm, precision contact sensor, MTC Vietnam Station successfully exhibited

BTFC1、BTF2、BT1220、BT20、BT2030、BT2040、B4A、BTS-5、MMP3

Warm congratulations to Ballsum for its successful exhibition at the MTC Vietnam Station on July 2, 2024.

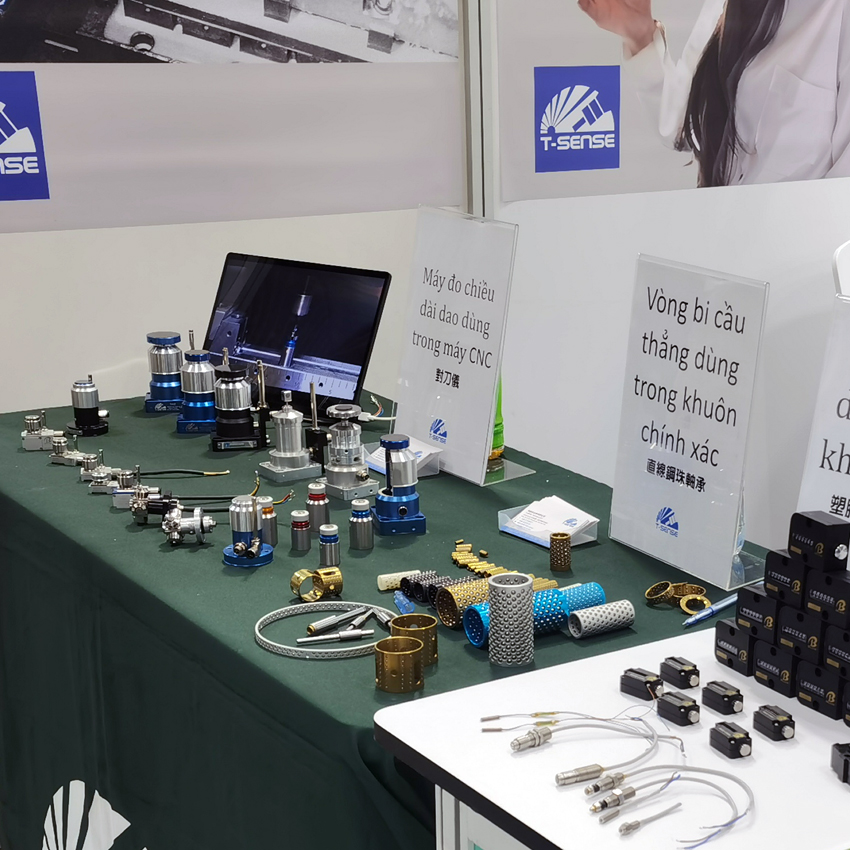

This time, at the 20th MTC Vietnam International Precision and Manufacturing Reshaping Exhibition, products such as workpiece measurement, machine tool contact tool setting probe, contact tool length measuring instrument, high-precision micro sensor, lathe tool setting arm, dispensing machine pressure sensor, precision manual tool setting instrument and workpiece measurement, mold counter, etc. were exhibited.

Some of these products are still popular in the Vietnamese mold and machining market and machine tool industry, especially the contact tool setting instrument.

The products include: BTFC1 dispensing machine tool setting instrument, BTF2 dental equipment tool setting instrument, BT1220 drilling and tapping machine tool setting instrument, BT20/BT2030/BT2040 machining center tool setting instrument, B4A CNC lathe tool setting instrument and other workpiece measurement instruments are favored by local customers. With economical and practical characteristics, the service life is up to 3-5 million times, the contact type has good anti-interference performance, and both new and old CNC equipment can be installed, which is a good way to meet market demand.

Here is a brief introduction to the use and function of Ballsum tool setting instrument

Use:

It is mainly used for CNC equipment measurement, machine tool origin positioning, correction of temperature drift and hysteresis caused by machine tool heating, and can accurately measure the position of the tool, tool origin setting, and tool loss and broken tool detection.

Function:

Automatic tool setting value, online detection of blade wear, tool length damage and broken tool alarm standby.

Product features:

Compared with traditional tool length detection methods (manual testing, trial cutting methods), it can save a lot of detection time, correct the cycle compensation displacement, set the tool offset with high precision and high reliability, the machine tool CNC system calls simple and reliable tool setting software, the machine tool automatically records, and eliminates human reading and writing errors.

Ballsum has been focusing on the production of online detection tool setting instruments and workpiece measurement, machine tool contact tool setting instruments, lathe tool setting arms, precision contact sensors, etc.

Focusing on operating products, providing professional supporting services, helping customers solve problems and achieve a win-win situation.