Ballsum teaches you how to choose a tool setting instrument for a machining center

Ballsum teaches you how to choose a tool setting instrument for a machining center, the principle of tool setting instrument, installation of tool setting instrument, and tool setting instrument service

How to choose a tool setting instrument suitable for machining center

The editor has carefully summarized some for your reference.

1. What should you pay attention to when using a tool setting instrument for the first time!

Choose the size of the tool setting instrument disk, which is often called the tool setting surface in the industry.

The selection of the tool setting surface is very important! The tool setting surface is directly related to whether the tool used in CNC machining can fully touch the tool setting instrument disk. If the diameter of the machining tool exceeds the diameter of the tool setting instrument disk, it cannot be completely detected by the tool setting instrument. At this time, the actual tool length of the tool is also omitted. The tool data measured by the tool setting program is not the actual tool length. It is easy to cause overcutting or breaking the tool during CNC machining, so be careful when choosing the tool setting surface!

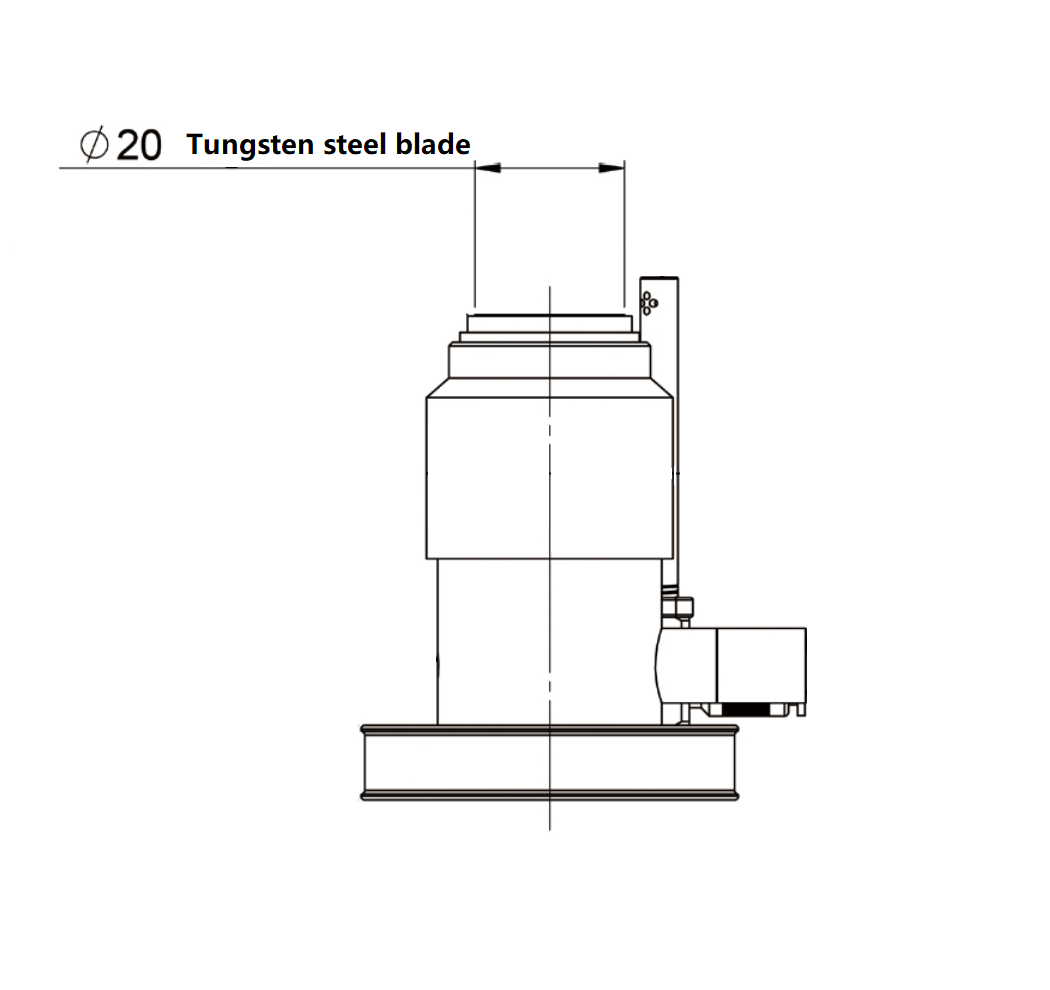

Among the common tool setting gauge contact surface diameters of ¢5, ¢10, ¢12, ¢20, ¢30, ¢40, ¢60, the common parameters are as follows: BTFC1, B4A tool surface ¢5, BTF2 tool surface ¢10, BT12 tool surface ¢12, BT1220, BT20, BTH1220 tool surface ¢20, BT2030 tool surface ¢30, BT2040 tool surface ¢40, BT2060 tool surface ¢60.

As shown:

2. How to choose tool setting gauge for large-diameter tools and micro-diameter tools:

For large-diameter tools, the tool setting gauge surface size can be selected according to the maximum diameter of the tool. It is best to select a tool setting gauge surface larger than the tool diameter.

For micro-diameter tools, the tip bending resistance should be considered, that is, the rebound force during tool setting. The greater the elastic force on the tip, the easier it is to break. How much elastic force can a general tool withstand?

For tools below ¢1, try to choose a tool setting instrument with a rebound force of 0.5N. For tools above ¢1, there is no need to pay special attention to the rebound force, as long as a suitable tool setting instrument is selected.

The contact force unit of the rebound force is Newton (N). The contact surface force of different types of tool setting instruments is different. The common parameters are as follows: BTFC1 series contact force 5N, BTF2, BT12 series contact force 1.5N, BT1220, B4A series contact force 2.0N, BT20, BT2030, BT2040, BTH1220 series contact force 2.5N.

3. Selection of tool setting accuracy of tool setting instrument:

Common ones on the market are 5um, 1um, 3um, and 5um.

There are two types of tool setting accuracy for BALLSUM: BTFC1, BTF2 series, accuracy: 0.5um, BT12, BT1220, B4A, BT20, BT2030, BT2040, BTH1220 series accuracy: 1um

The accuracy of tool setting refers to the accuracy of repeated tool setting when the tool setting is installed in a fixed position on the machine tool, and the Z axis of the machine tool is up and down or the tool setting axis is repeated back and forth, rather than the accuracy of the machine tool equipment after the tool setting is completed, and the tool is set again after a period of processing. The latter accuracy will be affected by the machine tool motion accuracy and tool wear.

4. The service life of the tool setting instrument is the issue that users are most concerned about:

BALLSUM factory quality department will regularly sample some products for each model and each batch, test the life of the tool setting instrument contact points, and perform continuous press tests in the laboratory to simulate the actual working environment.

Taking the BTF2 series tool setting instrument as an example, it takes three months to complete all tests after testing the contact life of 2 million times and the uninterrupted press test.

This includes the mechanical properties of the tool setting instrument, the waterproof function of the signal output online detection, the anti-aging of the electronic circuit and other technical performance evaluations. Only when the sample test is completely qualified can the finished product be officially put on the market.

The protection level of the tool setting instrument is IP level 68 (completely dustproof and waterproof, and can work normally under a pressure of 1 meter deep) certified by Taiwan SGS.

5. What system machine tools can the tool setting instrument be installed on? The mainstream common systems on the market:

Japan, FANUC, MITSUBISHI, MAZAK, OKUMA.

Germany, SIEMENS, HEIDENHAIN, REXROTH, FAGOR, Spain.

China, Huazhong CNC (HNC), Guangzhou CNC (GSK), KND, Weihong.

Taiwan, SYNTEC, LNC.

2. The process of purchasing a tool setting instrument:

1. How to choose a tool setting instrument and choose a more suitable tool setting instrument.

2. How to configure the tool setting instrument on the machine tool.

3. How to install the tool setting instrument.

4. Service time is 24 hours.

5. Machine adjustment test.

6. Acceptance confirmation.