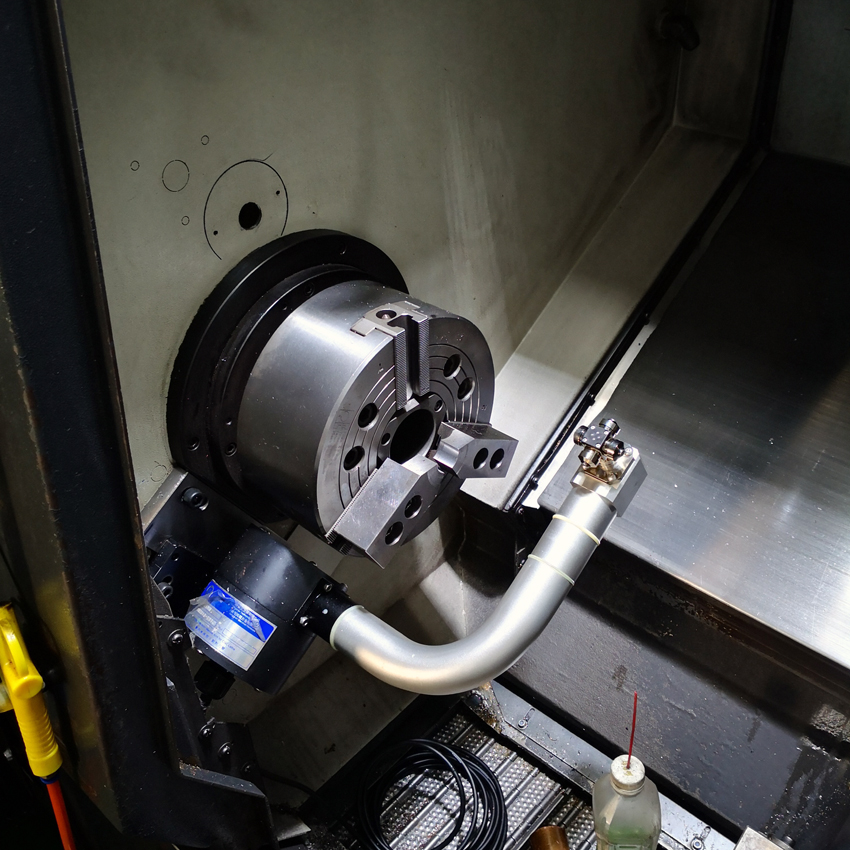

semi-automatic tool measuring arm for CNC lathes

Model: BTHM CNC lathe semi-automatic tool measuring arm

Origin: Taiwan

Repeat positioning accuracy: 1μm 2σ (speed 50-200mm/min)

Sensing direction: ±X, ±Z

Probe contact life: 2 million times

Probe repeat positioning accuracy: 1μm

Protection level: IP68 GSG certified cable (to interface box) specification standard 5m, non-standard length (customized)

Related products

Customer Service

Each customer is equipped with a professional technical engineer for one-to-one service

Provide 360° complete after-sales technical solution service

Main uses:

Tool measurement and tool damage detection on 2-axis and 3-axis CNC lathes

Main functions:

Automatic tool setting value, online detection of blade wear, tool length damage and tool breakage alarm

Product features:

It consists of a fixed base and a swing tool setting arm. During measurement, the tool arm swings to the measurement position, and the tool arm returns to the original position after the measurement is completed. The probe is stored in a metal protective box and can be directly controlled by the CNC system. It is suitable for mass production and fully automated production lines.

Compared with traditional tool length detection methods (manual testing, trial cutting methods), it can save a lot of detection time

Correct cycle compensation drift, set tool deviation with high precision and high reliability, the machine tool CNC system calls simple and reliable tool setting software, the machine tool automatically records, and eliminates human reading and writing errors.

Application equipment:

CNC lathe, turning and milling machine

Keywords: CNC lathe tool setter, lathe tool setter, imported lathe tool setter, exported lathe tool setter, retrofit lathe tool setter, turning and milling machine tool setter, 4-direction tool setter, precision lathe tool setter, TAKISAWA lathe tool setter, Doosan lathe tool setter, CNC lathe tool setter arm, CNC lathe automatic tool measuring arm, dual-spindle dual-turret CNC lathe tool setter arm