Micro-diameter tool setting instrument

Name: Precision manual tool setting instrument

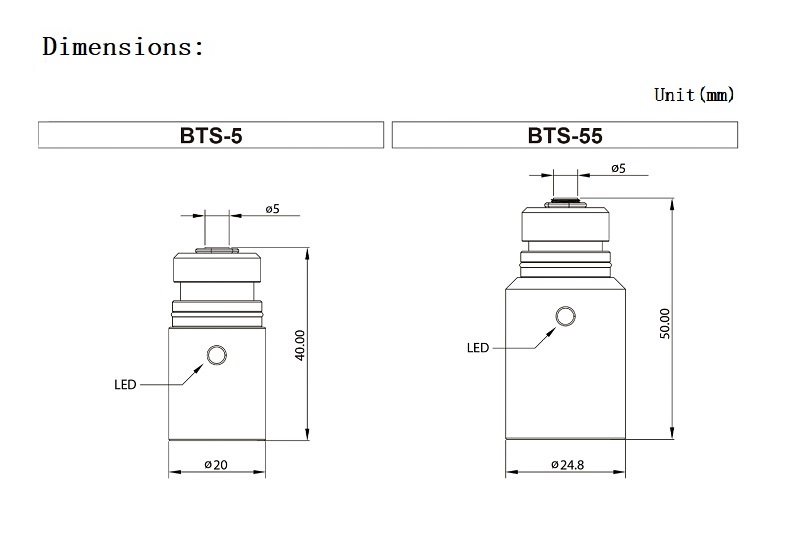

Model: BTS-5 BTS-55

Origin: Taiwan

Precision: Repeat positioning accuracy 1um

Contact life: 500,000 times

Contact force: 0.5N

Contact plate: Diameter 5.0mm

Sealing level: Dustproof, waterproof

Is it possible to replace the battery: Yes, model LR44*2

Related products

| BTS-5 | BTS-55 |

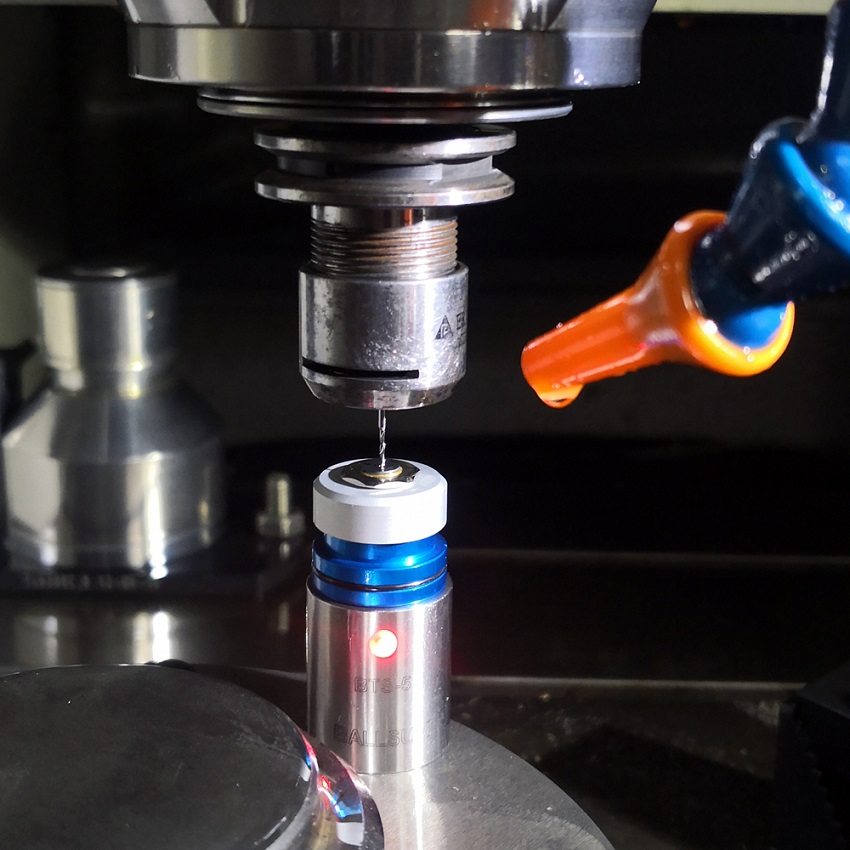

Manual contact high-precision LED display Z-axis setter

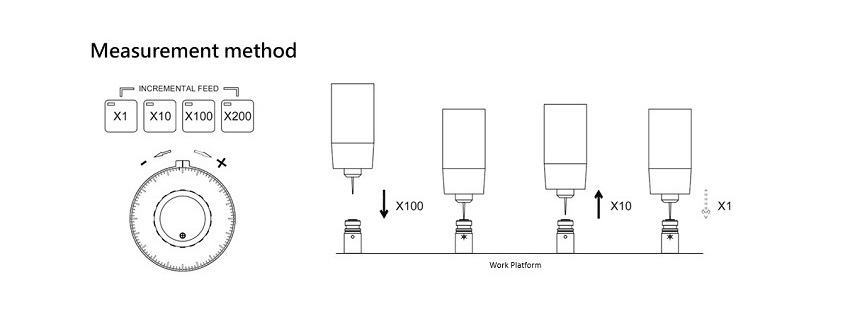

Place the BTS product on the work platform, move the spindle downward along the Z direction, and contact the tungsten steel contact surface of the sensing head until the LED light turns on. At this time, slowly move upward a small distance (until the light goes out), and then move downward at the slowest speed until the light turns on and stop. The Z-axis coordinate at this time is the height of 40mm (BTS-5) or 50mm (BTS-55) from the working platform.

Replace battery and bottom cover

Please use a Phillips screwdriver to open the bottom cover of the BTS-5 product, or use two-hole pliers to open the bottom cover of the BTS-55 product to install or replace the battery. The factory default is "magnetic bottom cover". If you have different needs, please replace it with a "non-magnetic bottom cover" part.

Things to note

The accumulation of dust will affect the accuracy and service life of the product. Please use a dust cover to protect the probe when not in use. (As shown on the right)

Although this product has a waterproof and dustproof design, it is still not recommended to be placed in an operating environment with cutting fluid and dust for a long time. It is recommended to put it in a storage box after use to protect the life of the product.

Can be used to measure the X-axis or Y-axis direction. Please be careful and avoid damage to the instrument due to dropping.

After the battery is exhausted, the button battery should be placed in the designated recycling place. Do not discard it randomly or mix it with garbage to affect the environment.

The product height is measured in a factory environment of 25±0.5℃. If operating in different environments, please use block gauges to compensate for product height.

Customer Service

Each customer is equipped with a professional technical engineer for one-to-one service

Provide 360° complete after-sales technical solution service

The tool setting trigger stroke of this product is almost "0" and the tool setting repeat positioning accuracy is 1 micron (um)

Product features:

Flexible tool setting, total tool setting stroke of 2.0mm, tool surface contact force of 0.5N to increase tool life

The height of each single product is calibrated with precision measuring tools, and the height measurement is accurate to microns (um). The spring pressure of the tool setting device is 0.5N, which is suitable for milling cutters and drills above 0.3mm.

Application equipment:

Used for small engraving and milling machines, glass grinders, machining centers, drilling and tapping centers, CNC lathes and other CNC milling, drilling and grinding bottom blade precise coordinate tool setting

Keywords: precision manual tool setting instrument, precision setter, photoelectric z-axis setter, micro-diameter tool setting instrument, micro drill tool setting instrument, Longjing micro-drill tool setting instrument, blade tip position measuring device