Tool setting instrument for drilling and tapping center

Brand: BALLSUM

Model: BT1220

Place of origin: Taiwan

Repeat positioning accuracy: 1 μm 2σ (speed 50-200mm/min)

Contact life: 3 million times

Contact force: preset 2.0N-2.5N

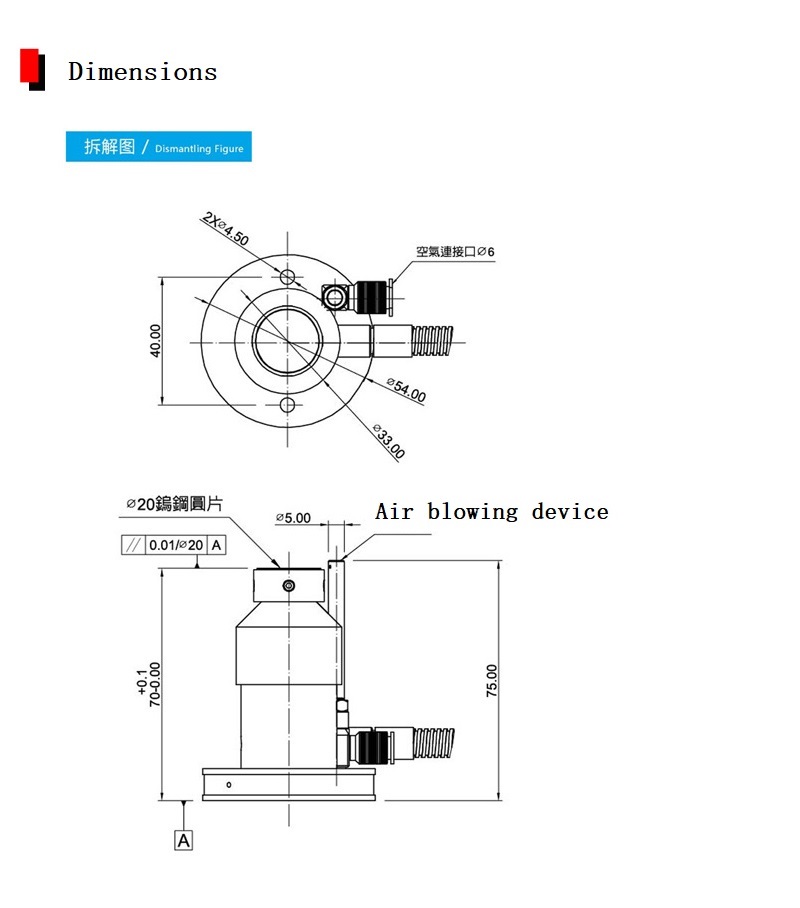

Contact plate: diameter 20mm

Sealing level: waterproof and dustproof, IP68 can work normally for a long time under the pressure of 1 meter of water

Cable length: metal protection tube 2.5M, cable 3M.

customer service

Each customer is assigned a professional technical engineer to provide one-to-one service

Provide 360° complete after-sales technical solution services

Product features:

It is an economical and practical contact tool setting instrument with a 20.0mm finely ground tungsten steel surface. The parallel accuracy of the body is within ±2μ. Even if the tool setting speed F value is 4000, it can be reliably detected with a repeat positioning accuracy of 1μm.

Due to its high precision, reasonable price, easy installation, stability and durability, it has been widely used in parts processing, 3C, mold processing and other industries.

Several advantages of tool setting instrument:

1. Reduce preparation time and manual input errors

2. Because it is an automatic measurement, there is no need for operators to be present and train operators

3. It can compensate for tool length changes that are difficult to see with the naked eye due to tool wear and thermal displacement

Product advantages:

Made in Taiwan, high precision, low contact force, reduced cost, high durability

Application equipment:

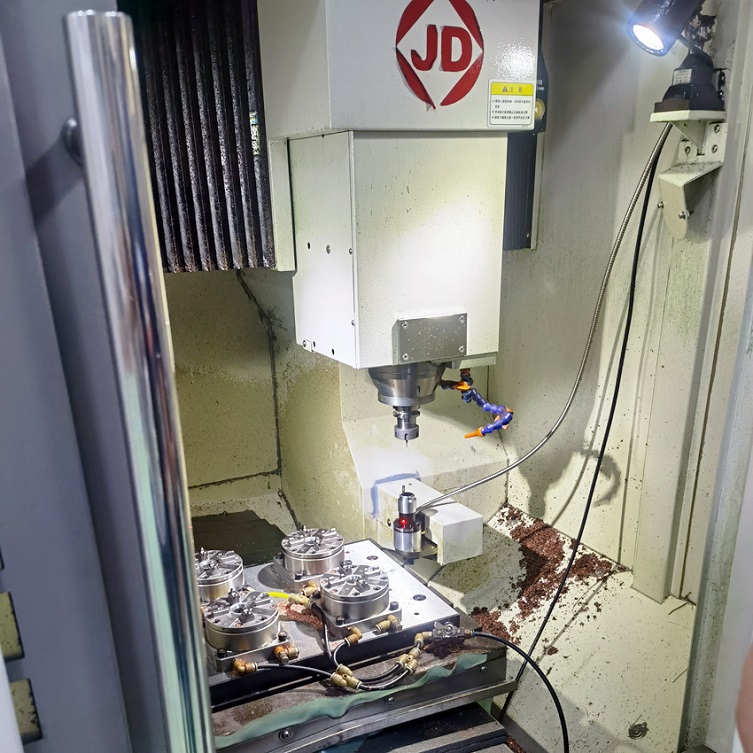

CNC machining center, drilling and tapping center, engraving and milling machine, precision engraving machine equipment

BT1220 Keywords: CNC machining center tool setting instrument, drilling and tapping center tool setting instrument, engraving and milling machine tool setting instrument, precision engraving machine tool setting instrument, BT1220 tool setting instrument